Extreme Manufacturing Explained

03-06-2013New location for my Scrum Trainings in Zurich

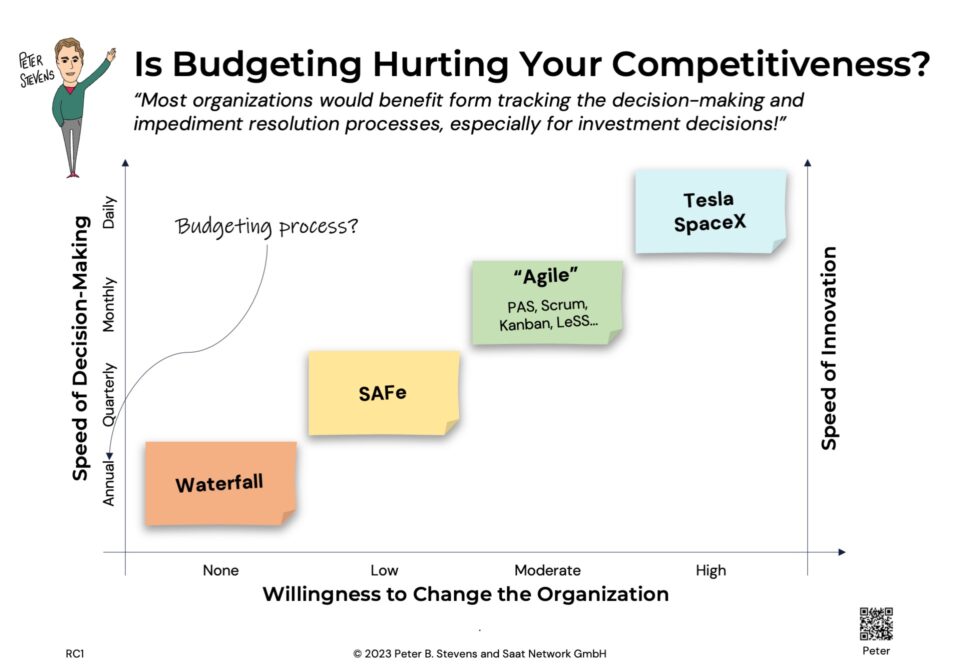

03-06-2013What happens if an engineer comes up with a way to build a safer car door? Can that new door be deployed right away? No. A stamping machine and a custom made die produce that door. Together they cost over 10 million US dollars and they must first be amortized before the new door can be economically produced. Given the high costs, it can take 10 years or more before that better door can enter production. You can see the impact of the need to amortize huge investments in the slow, incremental changes in automobiles from year to year, even from decade to decade!

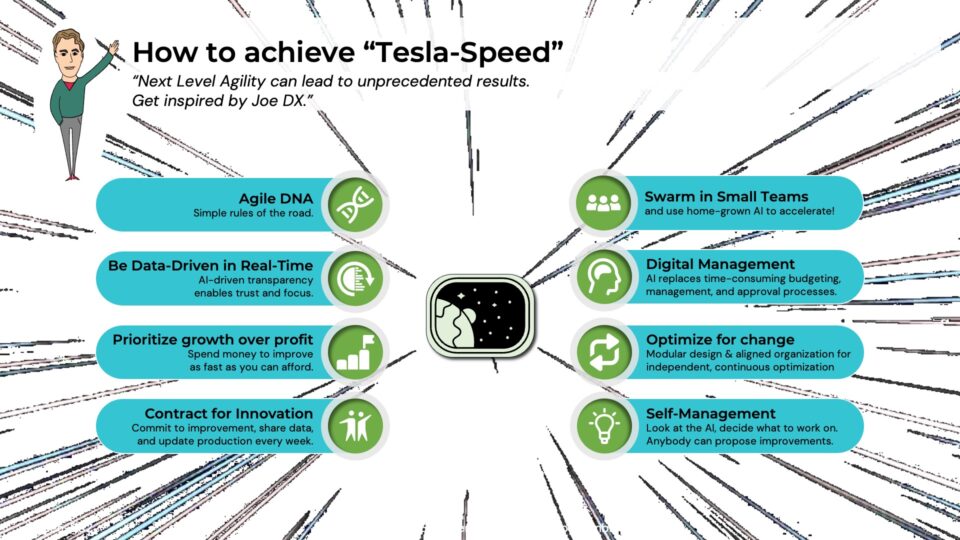

WIKISPEED can change their design every seven days. They employ tools like value stream mapping not merely to reduce the variance of products produced or to optimize the flow through the production line, but first and foremost to reduce the cost of change. It does not cost them more to use a new design than to use an existing design. So if they have a safer way to build the door today, they start using it next week.

Welcoming and responding to change represent core Agile values and principles (see the Agile Manifesto and the Principles behind the Agile Manifesto). So by adopting this principle, you take a huge step towards becoming an Agile organization.

Tomorrow: Object-Oriented, Modular Architecture

3 Comments

Hi Tom! eXtreme Manufacturing uses completely different tools and processes with those tools. It's more than only process, it's process that demands specific technical practices for mass manufacturing. Just like an assembly line didn't have craft work and custom casting stations as the core, instead that practice mandated interchangeable parts. To learn more about it, come get immersive hands on experience with us, build a car end to end with us using those tools and techniques!

https://www.kickstarter.com/projects/joejustice0/develop-extreme-manufacturing-class-and-curriculum

Hi Tom,

The short answer is by not having an expensive die.

Stamping pieces on a hardened die optimizes the unit cost in high volume at the cost of a very high price of change (i.e. you have to make many pieces before the cost of die is amortized). The leads to a 7 year product change cycle, as is the case with most cars today.

By selecting different technologies to make it easier to change — even though the unit cost is higher — you gain flexibility, thereby lowering risk and cost, especially start-up costs.

In the case of WIKISPEED, rather than using a hardened die to stamp metal parts, they used a styrofoam die, which is easy and cheap to create on a garden variety milling machine. They then lay carbon fibre on top of it, much like making a fibreglass canoe.

Cheers,

Peter

I don't understand this. How can they avoid the cost of a new custom made die for the door by having a different process?